Unveiling the Significance of China CNC Turning Parts in the Metal Fabrication Industry

China CNC turning parts have reshaped the landscape of metal fabrication, making significant improvements in precision, efficiency, and cost-effectiveness. As businesses continuously strive for competitive advantages, understanding the intricate world of CNC turning can be a game-changer. In this detailed article, we will explore the benefits, processes, and applications of CNC turning parts manufactured in China, showcasing why they deserve a prominent place in any metal fabricator's arsenal.

What are CNC Turning Parts?

CNC (Computer Numerical Control) turning parts are components that have been shaped through advanced machine tooling where computers control the movement of cutting tools. The turning process typically involves a rotating workpiece being cut by stationary tools, meticulously sculpting metal into precise shapes and dimensions. This process is integral in producing high-quality components for various industries.

The Process of CNC Turning

The CNC turning process consists of several critical stages, ensuring each component meets the required specifications:

1. Design and Prototyping

Before manufacturing begins, a precise design is created using CAD (Computer-Aided Design) software. This step is paramount as it dictates the final product's dimensions and functionalities.

2. Material Selection

The choice of material significantly influences the performance of the CNC turning parts. Popular materials include:

- Stainless Steel: Known for its durability and resistance to corrosion.

- Aluminum: Lightweight and excellent for intricate designs.

- Copper: Ideal for electrical applications due to its conductivity.

- Plastic: Used for parts needing insulation and light weight.

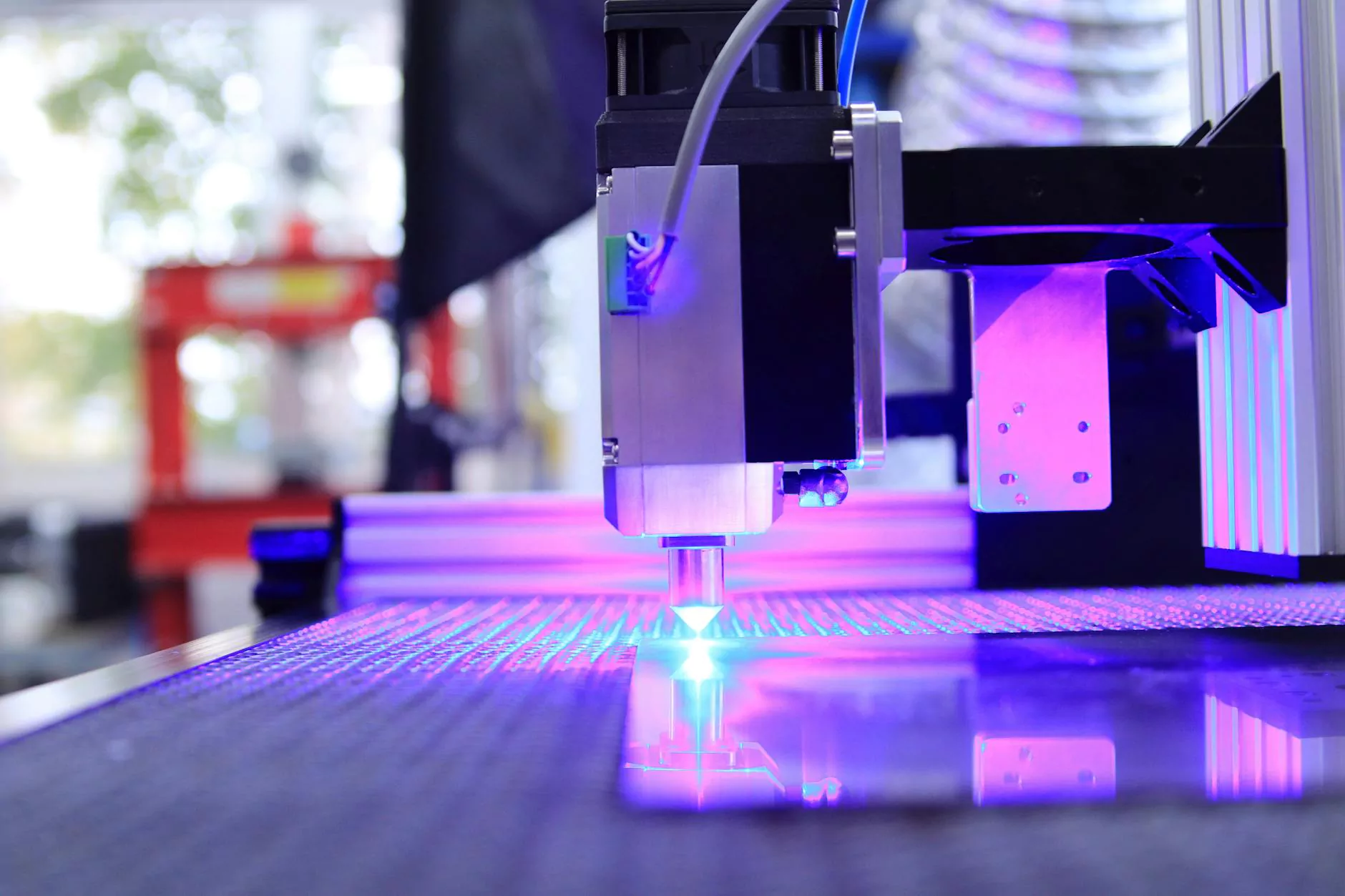

3. CNC Machining

In this phase, the selected material is fitted on a CNC lathe. Using the programmed design, the lathe rotates the workpiece while cutting tools remove excess material to achieve the desired shape.

4. Finishing Techniques

After the turning process, various finishing techniques such as polishing, anodizing, or coating ensure that the parts not only perform well but also have a visually appealing finish.

Advantages of Sourcing CNC Turning Parts from China

Choosing China CNC turning parts provides multiple advantages for businesses looking to enhance their productivity and streamline their supply chain:

1. Cost-Effectiveness

China's advanced manufacturing infrastructure allows for lower production costs. This means high-quality parts can be procured at much more competitive rates compared to other regions.

2. High Precision and Quality

Chinese manufacturers employ state-of-the-art CNC machines that ensure every part is fabricated with exceptional precision. This significantly reduces the margin for error, leading to higher quality outputs.

3. Speedy Production Times

With the ability to run multiple machines simultaneously, Chinese facilities can produce large quantities of parts in a shorter timeframe, ensuring that your projects remain on schedule.

4. Versatility in Manufacturing

This manufacturing capability means that businesses can request custom designs and adapt to changes in their production needs rapidly and effectively.

Industries Benefitting from CNC Turning Parts

Numerous industries leverage the advancements in CNC turning technology, including:

- Aerospace: Precision parts for aircraft and spacecraft.

- Automotive: Components that require high reliability and exact specifications.

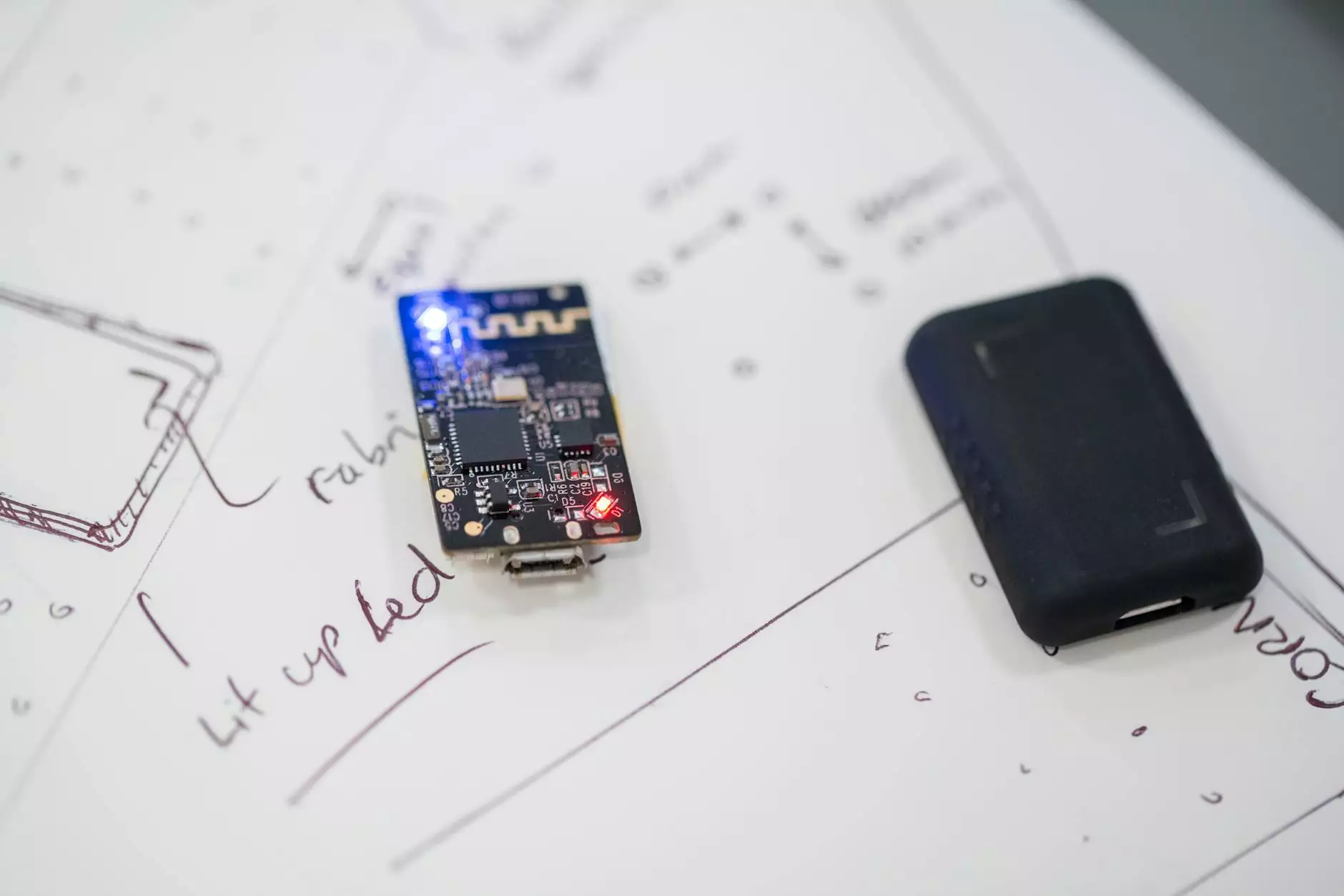

- Electronics: Parts for devices such as connectors and housings needing intricate designs.

- Medical Devices: Components that must comply with stringent regulatory standards.

Quality Control in CNC Turning Parts Manufacturing

To maintain high standards, quality control processes are imperative in the production of China CNC turning parts:

1. In-Process Inspection

Regular checks during the machining process help ensure that any deviations from the design specifications are promptly addressed.

2. Final Inspections

After production, parts undergo thorough inspection processes, often involving precision measuring instruments to confirm they meet the specified tolerances.

3. Certification Standards

Chinese manufacturers often comply with international standards such as ISO 9001, which signifies adherence to quality management principles.

How to Choose the Right CNC Turning Parts Manufacturer

Choosing the right manufacturer for China CNC turning parts is crucial for success. Here are key factors to consider:

1. Experience and Expertise

Look for manufacturers with a proven track record in your industry. This ensures a deep understanding of specific needs and regulations.

2. Technological Capabilities

Ensure that the manufacturer utilizes modern machinery and adheres to the latest manufacturing techniques. This technology directly influences the quality of the parts produced.

3. Customer Support

Effective communication is vital. Choose a manufacturer that provides dedicated support and is responsive to your inquiries and needs throughout the production process.

4. Reviews and Testimonials

Research past customer experiences. Online reviews and testimonials can provide valuable insights regarding quality and reliability.

Future Trends in CNC Turning Parts Manufacturing

The CNC turning parts industry is constantly evolving, influenced by advancements in technology and market demands. Here are some emerging trends to watch out for:

1. Automation

Increased automation in manufacturing processes will lead to further enhancements in efficiency and accuracy, allowing manufacturers to produce complex parts with minimal human intervention.

2. Advanced Materials

The industry is witnessing a shift towards innovative materials, like composites and lightweight alloys, enhancing the performance of components across various applications.

3. Integration of AI and IoT

Artificial Intelligence and the Internet of Things will transform production lines, enabling smarter processes and predictive maintenance, thus reducing downtime and waste.

Conclusion

In the realm of metal fabrication, China CNC turning parts stand as a hallmark of quality and efficiency. They empower businesses across various sectors to achieve unparalleled precision and innovation in their products. By leveraging the benefits of sourcing CNC turning parts from China, companies can gain a significant competitive edge, ensuring they remain at the forefront of their industries.

As a leading entity in the manufacturing domain, Deep Mould continually adapts to these trends, providing customers with state-of-the-art metal fabrication solutions. Partnering with us means aligning your business with a forward-thinking partner committed to quality, efficiency, and innovation.